MABR membrane

The traditional biochemical process involves treating wastewater by staying in anaerobic, anoxic, and aerobic tanks for a certain period of time before proceeding with back-end treatment. The main problem and limitation of this method is that the treatment effect is not ideal and the required site is large. However, most wastewater treatment biochemical processes currently use this method. Faced with the improvement of discharge standards, the disadvantages of traditional processes are exposed. As a “reverse diffusion” biofilm method, MABR not only has the advantages of biofilm water treatment, but also has unique advantages. Especially, the optional pure oxygen supply can further improve the ability of microorganisms to oxidize organic matter, and can avoid secondary pollution caused by blowing off volatile acids and other substances; In addition, in the process of achieving synchronous denitrification and carbon removal, nitrifying bacteria tend to adhere near the membrane biofilm interface, and the BOD in wastewater can be more efficiently used for denitrification.

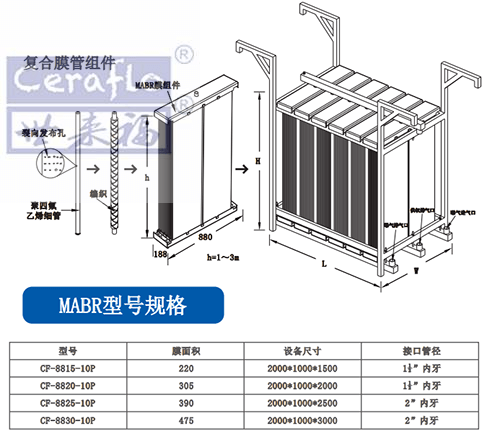

The Ceraflo-MABR membrane adopts a hollow fiber membrane structure, and is made of micrometer scale PTFE membrane filaments produced by independent patented technology. Allow the air inside the membrane to penetrate outward from the micrometer sized pores, resulting in a better increase in dissolved oxygen in water and lower energy consumption. There is a better improvement effect on the distribution of biofilms and the utilization of carbon sources, and most aerobic and hypoxic microorganisms will accumulate on the inner side of the membrane filaments. The MABR composed of this biofilm reaction unit can efficiently treat wastewater, reduce the size of the reaction tank, lower construction and treatment costs, and reduce land use.