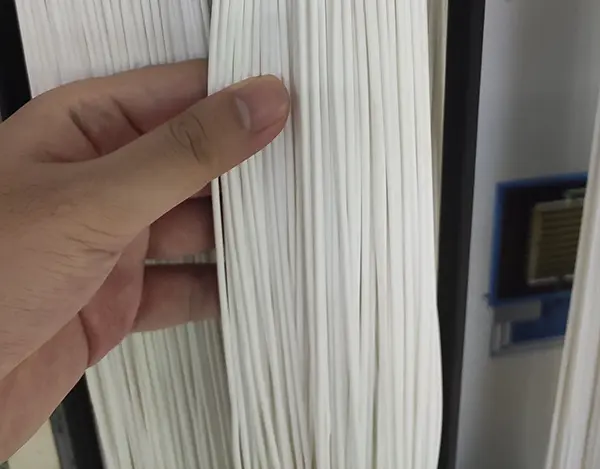

Hollow fiber membrane characteristics

1. Due to the excellent interception performance of the hollow fiber membrane, it can intercept various particles and colloidal substances. At the same time, because hollow fiber membranes have good mechanical strength and anti-pollution properties, they can be used to separate liquids or gases in industrial processes.

2. Due to the hollow structure of the hollow fiber membrane, it can effectively prevent the deposition of solid particles and colloidal substances on the membrane surface. Since hollow fiber membranes have high porosity, they can effectively improve gas or liquid permeability.

3. Since there are certain gaps inside the hollow fiber membrane, it will not cause secondary pollution. In addition, because there are certain gaps inside the hollow fiber membrane, the liquid can be initially separated, so there will be no phase change during the separation process and the original physical properties of the substance can be maintained.

4. Since the hollow fiber membrane has good anti-pollution performance, the permeability and filtration accuracy of gas or liquid can be improved during its application.

1. Application fields

Hollow fiber membranes are widely used in various fields due to their excellent performance. Currently it is mainly used in the following fields:

1. Environmental protection: The hollow fiber membrane has good anti-fouling properties and can adsorb or trap harmful substances in the environment on the surface of the membrane, thereby reducing the harm of harmful substances in the air to human health.

2. Food industry: In the food industry, it can be used to sterilize and preserve fruits, vegetables, beverages, and dairy products. This is because the hollow fiber membrane can effectively prevent the entry of bacteria, thus ensuring food safety.

3. Chemical industry: Hollow fiber membranes can be used to separate various impurities and components contained in different products.

2. Application effect

1. To separate liquids, different separation membranes are used according to different fluids, such as hollow fiber membranes for water separation, microfiltration membranes for oil separation, etc. Its main advantage is that when separating liquids, the greater the viscosity of the fluid, the easier it is to penetrate, and the smaller the pressure required, thereby reducing energy consumption.

2. It can remove impurities and reduce production costs. Since hollow fiber membranes have excellent permeability and filtration properties, they can remove impurities in water during water treatment. Such as heavy metal ions, bacteria, etc.

3. Has good chemical stability. The inner cavity of the hollow fiber membrane is made of high-purity polypropylene material without additives, which has high chemical stability.

4. Various trace elements can be separated when water is treated. Such as calcium, magnesium, sodium, zinc and other ions, which can effectively remove impurities in water.

5. No corrosion, scaling or clogging will occur during use.

6. It can replace filter cotton for filtration in industrial production, and can be used in oil-water separation, desalination and other fields.

7. Since the hollow fiber membrane has excellent mechanical properties and chemical stability, it can also be used as a filter bag.

3. Application prospects

Hollow fiber membranes have a wide range of application prospects, including seawater desalination, industrial wastewater treatment, air purification, sewage treatment, and medical and health fields. Hollow fiber membranes do not undergo chemical reactions during the preparation process, so they do not cause secondary pollution. They have high separation performance and can avoid phase changes during the separation process, so they can be used in a variety of different processes. Hollow fiber membranes have good high-temperature resistance, so they are widely used in the fields of food processing and beverage processing. They can also be used in seawater desalination, air purification, and industrial wastewater treatment.