The characteristics of hollow fiber membranes

1. It is resistant to pollution, has good chemical stability, and is resistant to strong acids and alkalis.

2. The membrane has high strength, good rigidity, high bending strength, and high tensile strength, and is not affected by air humidity.

3. It has high anti fouling properties because the hollow structure inside the hollow fiber membrane prevents pollutants from passing through, thus avoiding secondary pollution.

4. It has high resistance to high temperature and low temperature.

5. It has strong acid and alkali resistance and can still maintain good permeability and filtration accuracy in strong acid and alkali environments.

6. It has good mechanical strength, so its structural strength can adapt to hollow fiber membranes of different diameters, lengths, and materials.

7. Hollow fiber membrane is a separation membrane material that is not affected by chemical and thermal factors like other separation materials, so it can be widely used in industrial production.

1、 Separation principle

The separation principle of hollow fiber membrane is driven by pressure difference, utilizing the porous structure and special microstructure of hollow fiber membrane to achieve the separation of liquid and gas. Hollow fiber membranes are composed of micropores, with pore sizes typically several micrometers or even smaller. Due to the porous structure of the membrane, the flow rate of the fluid inside the membrane is greater than that outside the membrane. Therefore, hollow fiber membranes have advantages such as high permeability, high separation efficiency, and low operating pressure.

The design and manufacturing process of hollow fiber membrane structure is complex, and the material cost is high. The hollow fiber membrane separation device must be operated under pressure. If the pressure is too low, the fluid will flow out of the membrane; If the pressure is too high, the fluid will form a foam shape in the membrane, which will block the pore diameter of the hollow fiber membrane. Therefore, it is necessary to choose appropriate operating pressure and temperature based on the different properties of the fluid to ensure the safe and effective operation of the separation device.

2、 Separation method

Hollow fiber membrane is a semi permeable membrane that lies between liquid and solid. Due to its excellent pollution resistance, it can be used to achieve the separation of liquid and gas.

3、 There are two main separation methods for hollow fiber membranes:

1. Physical method: This method mainly relies on the diffusion effect of the membrane material itself, allowing the liquid penetrating the membrane to flow from one side to the other, thereby achieving the separation of liquid and gas. This method has the characteristics of simple operation and easy control, so its application range is relatively wide.

2. Chemical method: This method mainly involves the formation of various active groups with different properties on the surface of the membrane material, allowing the liquid that permeates the membrane to undergo chemical reactions, thereby achieving material separation. This method has the characteristics of high separation efficiency and low energy consumption, and has been widely used in fields such as petrochemicals, energy, and medicine.

Hollow fiber membranes have excellent filtration performance and can effectively separate impurities and microorganisms in water. Because hollow fiber membranes have good anti pollution performance, they have also been widely used in the food industry.

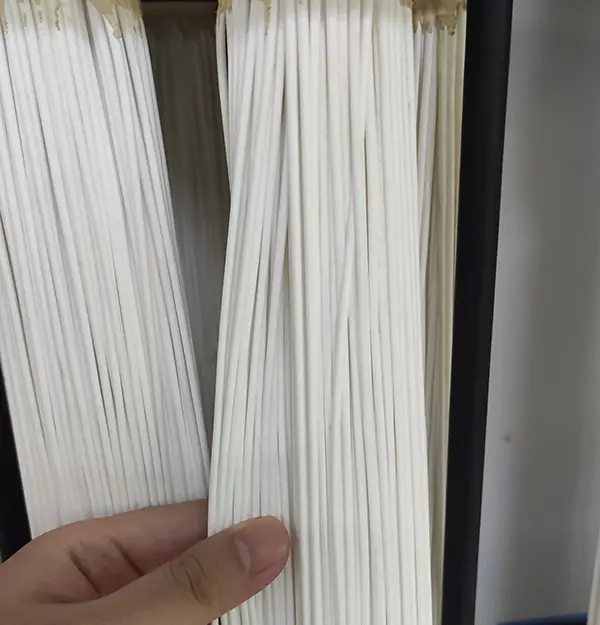

The structural form of hollow fiber membrane

1. A single filament hollow fiber membrane refers to a single filament formed by one or more hollow fibers intersecting with each other.

2. Multi fiber hollow fiber membrane refers to a hollow fiber formed by mechanical or chemical reactions of two or more single fibers.

3. Composite hollow fiber membrane refers to a multi-layer hollow fiber membrane composed of two or more different materials of hollow fibers, such as glass fiber, stainless steel pipe, aluminum foil, etc.

4. Plain weave hollow fiber membrane: Plain weave hollow fiber membrane refers to a membrane composed of two or more planes of different materials woven in both directions.

5. Three dimensional hollow fiber membrane refers to a three-dimensional structure composed of multiple membranes of the same material and different thicknesses arranged in a certain way on one membrane, which has many advantages:

(1) Due to the presence of multiple layers of membranes, the pore size distribution on each layer of membrane is uniform, thereby improving the filtration accuracy.

(2) Due to the uniform distribution of hole sizes on each layer of membrane, impurity filtration is relatively thorough.